Precision Metal Cutting Services (Laser Cutting & Water-Jet Cutting)

Precision Fiber Optic Laser Cutting

Fiber optic laser cutters utilize amplified light that is channeled through a fiber optic cable. The light is then straightened and delivered by a lens that is hyper focused on the material being cut. This delivery system provides extremely accurate cutting of numerous types of materials in various thicknesses. Laser cutting solutions display extraordinarily high electrical efficiency, which results in lower customer costs. The advanced quality benefits are:

a. Helical Rack & Pinion Drives – These advanced drives allow for the higher torque motors to achieve smoother and quicker acceleration.

b. Automatic Gas Selection Assistance – This feature allows the machine to automatically choose the proper gas for the material being machined without operator intervention.

c. High Speed Laser Head – The head features a fast sensing processor that allows for increased speed rates and enhanced height sensing control.

d. Cartridge Style Lens Holder – The head also features a cartridge assisted lens holder that allows for quick setups between different materials, without the need for tools.

e. 4-Station Nozzle Changer – Nozzle changes are simple with 4-station design, which allows for quick and easy exchanges.

f. Touchscreen Controls – Easy to operate touchscreen allows for efficient network access, which allows you to retrieve programs generated offline.

g. Thumbnail Screen Views – Allows for quick and easy part identification.

We provide custom laser cutting for one-off projects or batch orders and deliver cost-competitive, high quality laser cut parts consistently and to our customers’ exacting technical requirements. We work with ferrous and non-ferrous metals and are able to cut up to 6mm in Stainless steel, 4mm in aluminium and up to 15mm in mild steel.

How Ego Can Help you

With software import capabilities from DXF & DWG files, CAD designs quickly become finished parts as our software driven CNC Laser Cutting equipment quickly and efficiently process them, leaving minimal waste.

Ego’s ability to cut thinner gauge material increases the high level of intricacy and accuracy when delivering precision Laser cutting in the manufacture of small, through to large part orders – all made from flat sheet metal.

Our skilled sheet metal fabricators process custom sheet-metal jobs quickly and accurately with a high quality outcome. We are able to produce apertures and intricate pieces to a very high degree of accuracy and finished parts and components with smoother surface detail with clean square edges that are practically burr-free across holes and edges; while generating less material waste than conventional stamping processes.

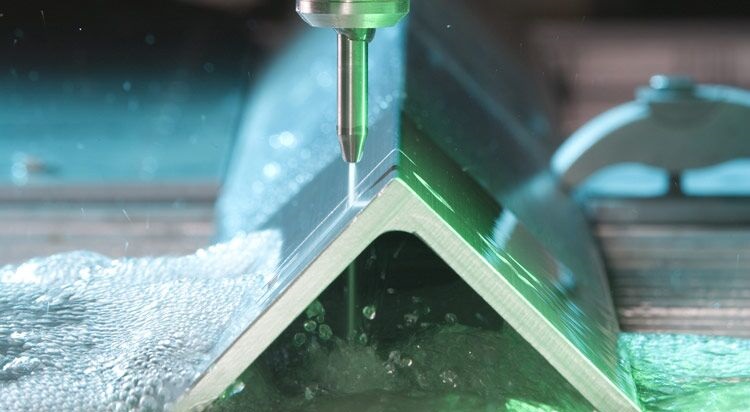

Precision Water-Jet Cutting

At Ego Manufacturing Group, we use state-of-the-art waterjet cutting technology to ensure superior precision and quality for our metal parts. Engineered for faster, smoother, and more precise cutting, our leading-edge machine provides instant feedback to the motor control system to maintain ultra-precise cutting head motion and tracking.

Advantages of Water Jet Cutting

a. Can machine a broad range of materials and thicknesses

b. CNC programming for very fast cutting speeds (up to 500” per minute) and exceptional precision (±0.003”/±0.076mm or better)

c. Water jet cutting does not create heat-affected zones or mechanical stresses in the material

d. Uses no tooling and only minimal fixturing for increased productivity and reduced cost

e. Water jet cutting produces a smooth edge on machined parts, reducing the need for secondary finishing operations

f. The environmentally-friendly process uses only water and natural garnet abrasive as cutting media

g. Large work envelope for machining larger parts (X-Y axis:10’ × 5’2”/3,048mm × 1,575mm; Z axis: 12”/305mm; work table 12’2” × 5’8”/3,708mm × 1,727mm)

h. Near perfect repeatability within ±0.001”/±0.025mm or better

Ego is the one of the best source you need for high precision sheet metal fabricated parts. We offer water jet cutting, metal stamping, metal welding, precision cnc machining and more, to give you parts that match your exact specifications. Contact us to get a best price for your project today.